A multi tyre roller, also known as a pneumatic tyre roller (PTR), is a type of compaction roller that uses air filled Rubber tyres to compact the underlying surface area. When applied correctly, it can be the difference between a professional finish or one that catches your eye for all the wrong reasons.

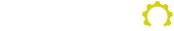

By using overlapping smooth tyres without tread on both the front and the rear axles, the multi tyre roller is able to eliminate gaps, giving complete and uniform compaction coverage over the entire compactive rolling width.

As mentioned it also features a unique overlapping design between the front and rear axles. This produces a massaging or kneading effect of the material being compacted between the tyres of the front axle, before doing the same at the rear. This produces excellent results by driving larger partials lower into the ground and also sealing the top layer during compaction. It’s primarily effective in softer terrain such as soil, but can be very handy for finding spots in your job via and initial “proof roll” and compacting more rigid and stubborn surfaces as well.

So, now that you’ve got a better understanding of what multi tyre rollers are all about, let’s dive deeper!

Where do multi tyre rollers work best?

Multi tyre rollers are one of the hottest properties in Conplant’s hire fleet because they’re so versatile. They’re always tricky to hire – because someone else has gotten there first!

Multi tyre rollers excel in a large range of project applications and on a large range of materials. They can be used for:

- Maximising the production of asphalt finishing and sealing

- Proof rolling

- Maintaining / Stabilising Regional or rural roads

- Soil compaction including granular and semi cohesive soils.

Multi tyre rollers can also be used on several different projects such as asphalt applications, highway construction, road maintenance and construction, large civil engineering projects including subdivisions streets or large parking areas, and even small construction projects like driveways!

What are the main benefits of using multi tyre rollers?

When looking at the key benefits of multi tyre rollers, it’s hard not to compare other rollers such as steel rollers or static steel rollers to really understand the difference.

For example, when compared to steel rollers, multi tyre rollers have a greater ability to achieve a more uniform degree of compaction and an increased level of compaction density via their varying weight range.

They’re also incredibly comfortable and easy to operate with great vison due to cab height & size, ergonomic controls, sliding seats and improved braking and steering assemblies (on newer models of course).

These ergonomic controls & vision allow the operator to easily focus on compacting the surface whilst maintaining a safe working environment, eliminating the need to constantly adjust the controls or even frequently moving the seat just to get a clear line of sight to the roller.

You’d be forgiven for thinking that these newer intuitive controls would require additional levels of training or practice – they’re actually often less technical than vibrating rollers, and newer operators of all experience levels will find them supremely easy to operate to achieve the best compaction finish.

While newer models may have important technology improvements, older multi tyre rollers can still get the job done. Both newer and older multi tyre rollers have the same basic build. They consist of a heavily loaded body, some even featuring adjustable ballasting systems with a row of 3,4 or 6 closely spaced tyres which are usually overlapped.

And of course, the same rubber tyres which provide uniform pressure throughout the width of the roller to create a smooth and even surface.

Advantages of a multi tyre roller compared to a static steel roller:

Let’s look at the other high level benefits between a multi tyre roller and a static steel roller.

- Multi tyre rollers provide a more uniform degree & finish of compaction compared to steel wheel rollers.

- They provide a tighter, denser surface thus with a “capping” effect decreasing permeability of the top or wearing layer.

- They provide increased depth of compaction density that many times cannot be obtained with steel wheeled rollers.

- They compact the mixture via a “kneading” effect without causing checking (hairline surface cracks) and they help to remove any checking that is caused with steel wheeled rollers.

- They provide a consistent check of surface compaction highlighting “soft spots” with individual tyres / points “proof rolling”.

What size multi tyre roller do I need for my project?

When selecting a small 1.8t multi tyre roller, a large 40t model, or something in between, it all comes down to the size and type of your project.

Smaller multi tyre rollers, up to 3.5t, are perfect for small construction projects such as driveways, car parks and repair work. This is thanks primarily to their overall size and their incredible manoeuvrability, making these smaller multi tyre rollers perfect for tight applications or for areas that have a reduced access such as under carports or in confined spaces.

Mid-sized multi tyre rollers ranging between 5t to 16t are perfect across a whole host of larger scale projects including road maintenance and construction, large civil engineering including subdivisions streets, repair work or large parking areas and driveways. This is thanks to the increased weight and larger overall compaction width to help keep up with production requirements.

Larger multi tyre rollers ranging in weight from 16t to 28t are suitable for larger civil engineering projects including highway construction, major arterial roads and avaiation and major hardstand applications.

The largest multi tyre rollers, coming in at 40,000kg, are specially designed to provide deep-lift compaction for hardstands, earth fills and subbases, and are perfect for use on large infrastructure projects – think several kilometre long highways and major arterials or even airport runways & taxiways.

Can I change the weight of my multi tyre roller?

Sometimes you might have a multi tyre roller that is perfectly equipped for one project, but for another, it’s far too heavy, or perhaps not heavy enough, and could be potentially hazardous or result in poor quality of compaction.

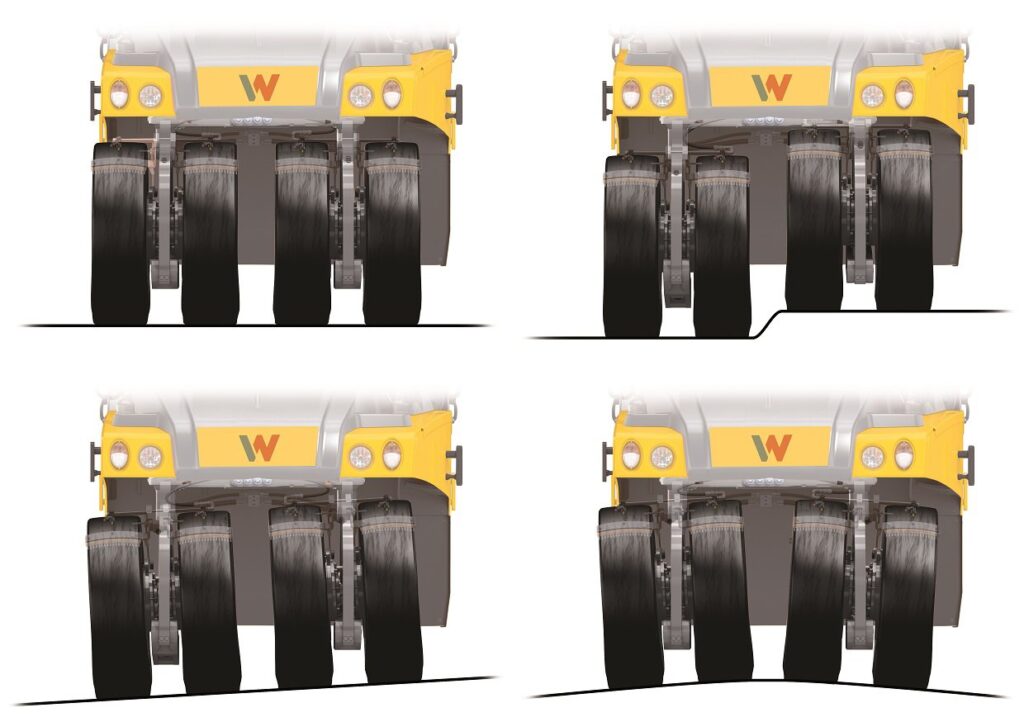

Fortunately, multi tyre rollers are often manufactured in a way that enables the overall weight of the unit to be increased or decreased. This is done by adding or removing compartments filled with water, steel concrete or sand weight from the ballast compartment.

We call this ‘easy ballasting’, and it allows the machines to be adjusted to the ideal weight for a wide range of jobsites.

Compartments for ballast materials are usually built into the frame or added to the underside of the machine. This makes for easy and convenient adjustments, the ability to maintain weight consistency and prevents the need for purchasing or hiring other machines due to weight concerns.

And there you have it! That’s everything you need to know about multi tyre rollers. So, the next time you have a project in the pipeline and need to compact a surface for a smooth, gapless and crackles finish, you know exactly which multi tyre roller to hire.

Got a project that’s coming up a lot sooner than you thought? No problem. With Australia’s most comprehensive roller hire fleet, we’ve got the multi tyre roller you need for your next big or small project. Send us an enquiry or give us a call on 1300 166 166. Our experts are happy to help