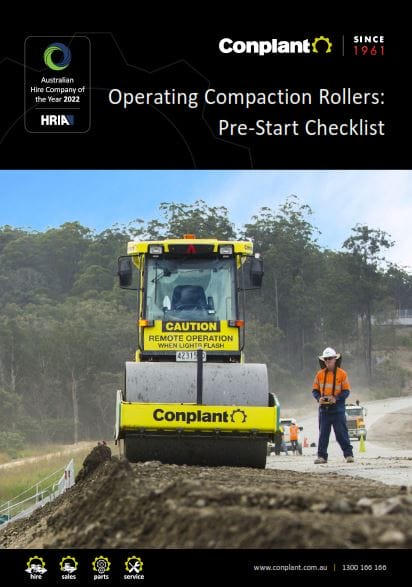

Compaction Rollers - How they work and how to operate one (a detailed checklist to get you started)

Looking at hiring a compaction roller for your next job? There’s a lot to consider with many different roller options to explore – so lucky the Conplant team is always available to help you through it.

In this blog, we want to give you a rundown of what a roller does and how to get started in the safest possible way, so that you’re all set for spectacular results.

Ready to get rolling on your next project? To help you with a super safe operation, we’ve put together a Roller Operation Prestart Checklist that you can access and share with your team.

So, what is a compaction roller

Quite simply, a roller is a piece of heavy machinery that does all the groundwork for you. It compresses Soil, Asphalt, Clay and other granular elements to remove air voids that will ensure robust load bearing capacity. No matter what you’re constructing, from a driveway to a skyscraper, a compaction roller can:

- Reduce granular settling and shrinkage over time.

- Ensure a reduction in water seepage.

- Reduce swelling and contraction.

- Make your surface stable for foundational work.

Once you’ve identified the need for a compaction roller on your job, you can begin the search for the roller that best suits the task at hand. And once decided, you’ll need to know how to operate that roller, beginning with a pre-start process that’s detailed in our complete roller checklist below.

The different kinds of rollers

When it comes to compaction work, it’s not a one size fits all situation, there are a slew of different kinds of rollers to consider for a perfect project pairing. Choosing the right compaction equipment for your job is an essential step in getting the best results possible.

To ensure the right selection is made, there are a wide range of factors, to consider:

- The nature and size and location of the job.

- Distance and accessibility.

- The deadline.

- Type of material to be compacted i.e soil, asphalt or clay.

- Volume and depth of compaction.

- The desired finish on the project.

Choosing the best compaction roller is key to fast-tracking results and exceeding expectations with a compacted surface with optimal load bearing capacity with and a stunning finish. Ideally, the right roller should minimise the number of passes needed, for a reduction in fuel and time until completion.

Rolling into Perfection: Exploring Various Types of Compaction Rollers

Tandem rollers are optimal for most general civil applications, road construction projects, parking lots and driveways.

Static three point rollers suit residential areas close to sensitive areas, buildings or bridges, where vibrations can be potentially hazardous and well suited for proof rolling.

Smooth drum rollers give you a great finish on mixed or graded granular material like bases, sub-bases and non cohesive soils.

Padfoot rollers are ideal for working with Clay / cohesive soils and other materials in preparation with sub base.

Combination rollers are well suited for Paving and footpath applications and leave you with a great finish on asphalt compounds and other mixed granular materials.

Multi-tyre rollers are a go-to for compacting and finishing off Asphalt. They are also well suited to maintain & compact unpaved roads & mixed soils.

Trench rollers are perfect for pipework, utility & all general small-scale compaction projects applications with cohesive and semi cohesive soils.

Pairing the right roller with the right environmental conditions is crucial.

If you’re dealing with a steep slope (gradient), you might need something smaller, whereas a land slope might require a nimble or remote-controlled roller to nail the task.

Once you’ve settled on the best roller for the job, you need to call Conplant and order it! An expert can further help you with the selection process, and give winning advice for getting the best out of your gear, while avoiding nasty surprises, job blowouts, or worse.

Still unsure which is the right roller for your next job? Our sales team is ready to talk you through all the particulars of our compaction roller catalogue, and walk you through the process of how to compact soil with a roller.

How to operate compaction rollers

Once your roller has been delivered to your site, it’s not as simple as jumping in, click clack, and off you go. There are lots of boxes to check before you get rolling. It’s now essential to initiate a pre-start check for the safest possible operation of your roller. Without a pre-start, there are a myriad of factors that could seriously mess with your progress. A pre-start ensures you:

- Keep you and your team safe at all times.

- Avoid any delay times with equipment failure.

- Identify parts that might need maintenance or replacement.

- Avoid overheating.

- Maximise the service life of a roller.

Put simply, a pre-start check is a quick review of the roller you are about to initiate, to ensure it’s safe and ready for the job. The last thing you want is an incident that puts you and your team behind the eight ball,or compromises yours or anyone else’s safety onsite.

A pre-start involves the inspection of your equipment before use, so flaws/defects can be detected early and eradicated. Factors like overheating or faulty parts that need to be repaired or replaced can be nullified there and then, as to avoid mechanical failure or a breakdown that hurts productivity or that can potentially create a site Hazard.

Pre-start checklists are provided with all Conplant hired equipment, however if you own your own gear you should take a look at your operator manual for specifics relating to your piece of equipment.

Get our comprehensive Prestart Checklist now

Conplant supplies some of the highest quality compaction rollers in Australia, but to maximise effectiveness, they need to be paired with pristine safety protocols. That’s why we pulled together an all-encompassing Compaction Roller Operation Checklist. Ideally, before each session on a roller, you’ll make time to run through and check off every box, so that your roller is deemed as ready as you are to smash the task at hand with the utmost efficiency.

Get our comprehensive Checklist now

Please enter your details below for the complete checklist to be sent directly to your inbox. With this checklist in tow, you can be confident in knowing that every measure has been taken to ensure a safe and successful compaction session on a Conplant Roller.